Search

Fuel Polishing for Marine and Boating

section-ba088a0

WASP PFS’s sister company Separ UK has been a key name in the Marine Industry since the 1980s.

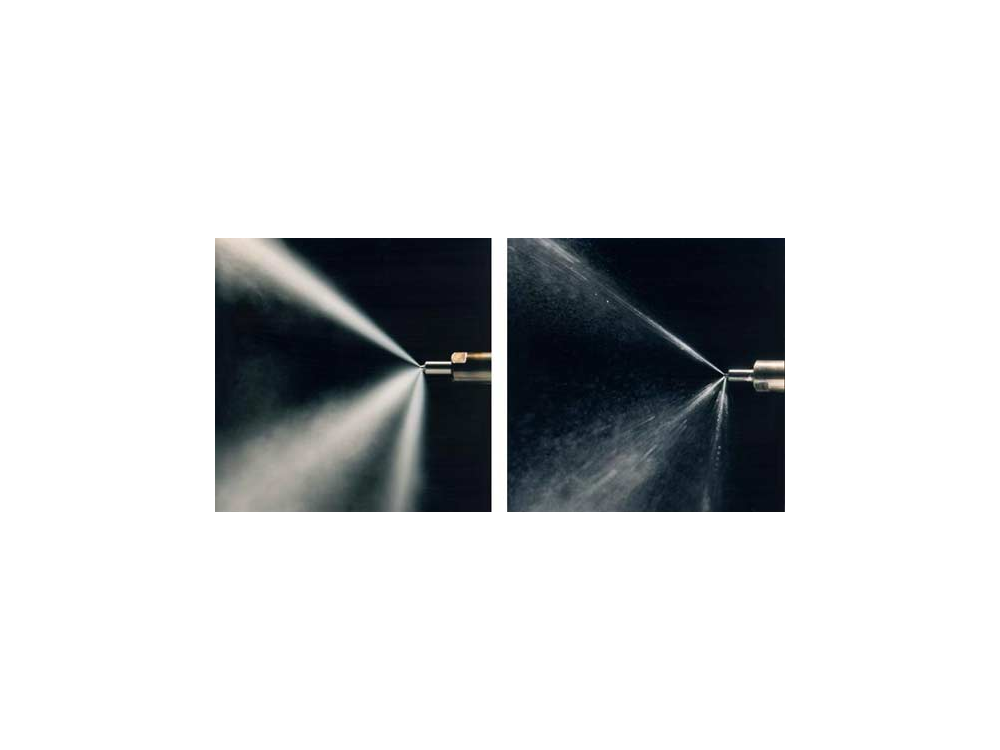

Our customer feedback has made us only too aware of the issues caused by low grade fuel in certain countries where boats may be sailing to and filling up. Fuel can be already be contaminated with sediment, bacteria and water beforehand, leading to blocked injectors and engine damage and potential engine failure. Not to mention the presence of water and risk of condensation which is the main cause of injector and engine damage and a breeding ground for bacteria.

Damaged injectors and contamination lead to poor performance, reduced efficiency, high fuel consumption and potentially engine damage and costly repairs.

While on-board in-line filters remove contamination as the fuel is being used, if the fuel is stagnant in the tank with water and bacteria within the sump, eventually it will reach the fuel line. The fuel, complete with a mass of bacteria, blocks the filter element, starves the engine and hence a power failure occurs.

This is where Fuel Polishing comes in.

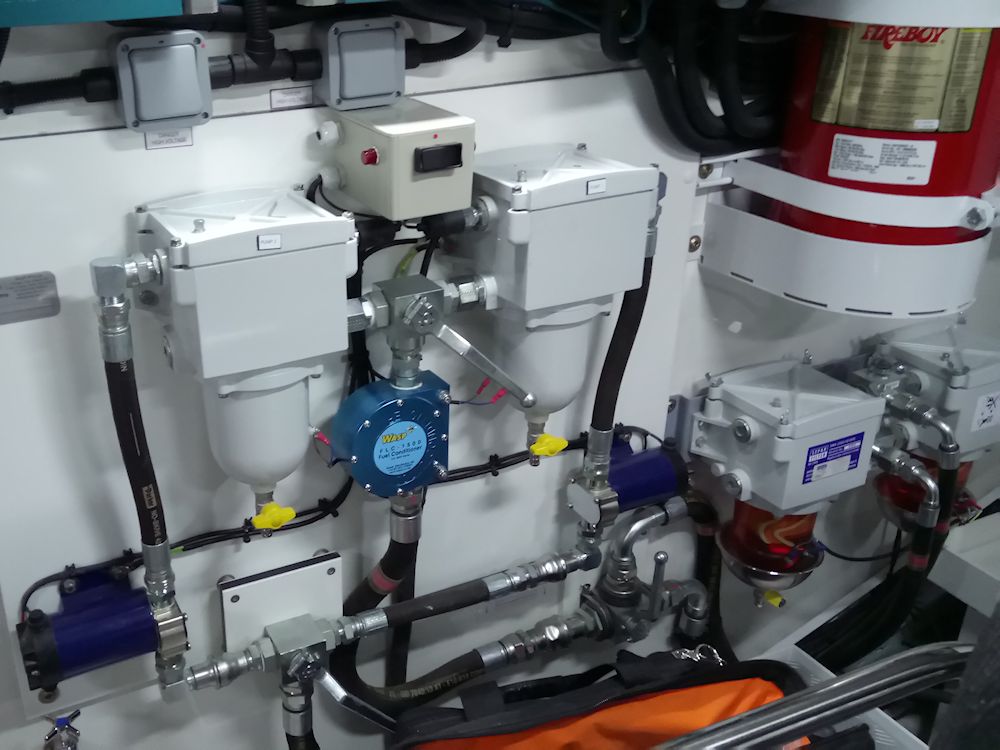

A fuel polishing system with its own inbuilt pump will regularly clean the fuel whilst removing water and bacteria. In doing so, it removes the infection before a complete power failure can happen.

The Marine and boating industry acknowledge the potential catastrophic consequences of being out in open water with no power, hundreds of vessels around the UK and countless more worldwide are now protected with on-board fuel polishing units from WASP PFS Ltd.

If you are new to fuel polishing, our guide to fuel cleaning explains how fuel polishing works.

[SLGF id=2879]

section-e72a926

Fuel Contamination

Exposure to water results in fuel contamination from water itself, as well as the bacteria it breeds.

Oil Change Made Easy

Our Oil Change Systems are ideal for the marine industry to quickly and easily change oil in up to 8 ports.

section-1c63ecf

Request more information or a quote

Notice: JavaScript is required for this content.